Basic Types Of Sheet Metalworking Operations

Cutting bending drawing.

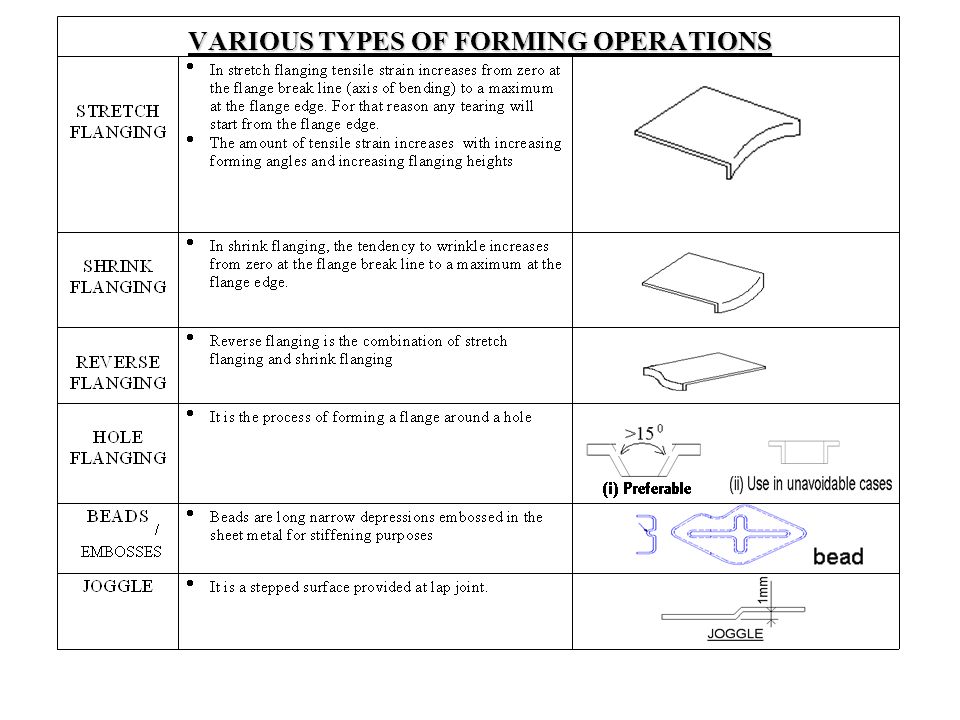

Basic types of sheet metalworking operations. Cutting operations and forming operations. Types of fits references external links. Forming cutting and joining. Under these two categories there are a number of other types of operations.

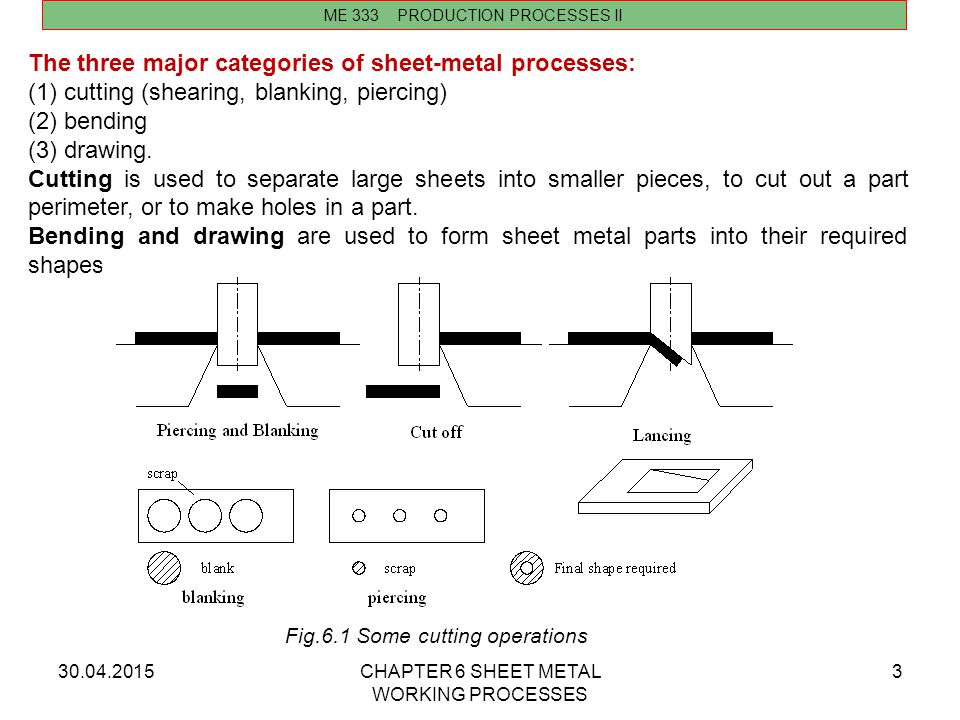

Bending is a manufacturing process that produces a v shape u shape or channel shape along a straight axis in ductile materials most commonly sheet metal. The first one is sheet metal cutting second one is sheet metal bending or forming and the last one is known as deep drawing. It is a type of bending operation in which a piece of sheet metal is fixed or held between two dies from one end as shown in the fig. By physical removal of the material from the sheet if the required shape of the component is obtained called as cutting or shearing operation.

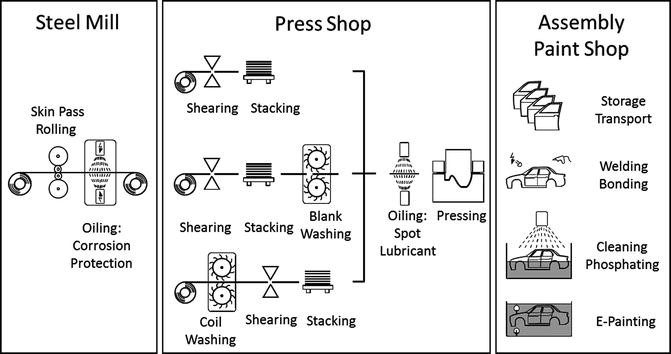

I hope you liked the article if so don t forget to share your thoughts in the comment section and also spread the knowledge in your favorite social media platform. The three basic types of sheet metalworking operations are 1 cutting 2 bending and 3 drawing. So this is a detailed explanation of different types of dies used in sheet metal operations. Cutting and forming thin sheets of metal usually performed as cold working sheet metal 0 4 1 64 to 6 mm 1 4in thick plate stock 6 mm thick advantage high strength good dimensional accuracy good surface finish economical mass production low cost.

Commonly used equipment include box and pan brakes brake presses and other specialized machine presses. The die diameter equals the blank diameter and the punch diameter is smaller by twice the clearance. Identify the three basic types of sheet metalworking operations. Press working operations or sheet metal operations.

Metalworking generally is divided into three categories. Prior to most operations the metal must be marked out and or measured depending on the desired finished product. Then the other end is forced to strike upon the punch which is free or unfixed. Each of these categories contains various processes.

Define drawing in the context of sheet metalworking. Mainly sheet metal process can be divided into three types. Thus the free or unfixed edge of the sheet metal piece is bent to make the forming process. Drawing is a sheet metalworking operation used to produce cup shaped or box shaped or other complex curved hollow parts.

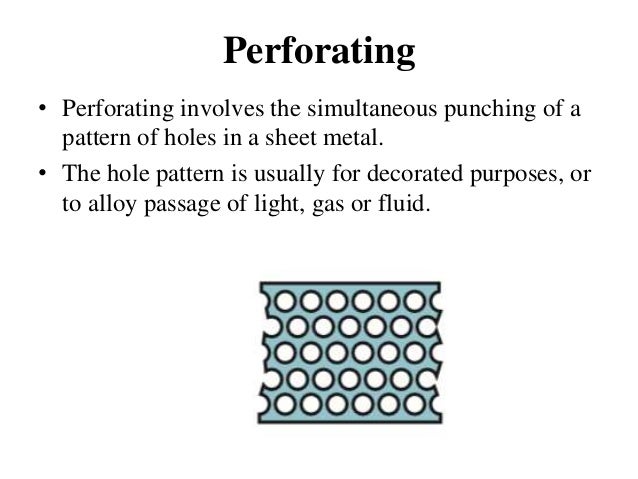

The different types of sheet metal operations can fall under two different categories.