Bending 1 8 Thick Aluminum Sheet

Free shipping on many items browse your favorite brands.

Bending 1 8 thick aluminum sheet. For 0 25 in thick 6061 in an o condition the material supplier may specify a 1 to 1 inside radius to plate thickness ratio. Thick this metal angle is commonly used for constructing this metal angle is commonly used for constructing bicycle racks bed frames motor mounts and many other utilitarian functions. Fuel tanks food chemical handling trailer siding roofing etc. M d building products 1 ft.

M d building products 1 ft. How to bend sheet metal without a brake. For 0 5 in thick it s 2 times the thickness. I don t remember the cost but but it was resonable.

Diamond tred aluminum sheet heavy weight model 57575 13 49 13 49. How to bend sheet metal without a brake in 4 different methods with minimal or homemade tools. Union jack aluminum sheet in graphite model 57571 19 98 19 98. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.

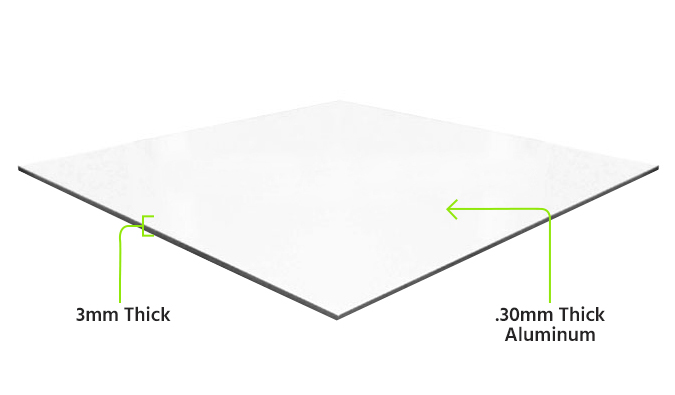

As the thickness increases so does the minimum radius. In 0 375 in thick aluminum the minimum radius is 1 5 times the thickness. The minimum bend radius data shown in these charts is measured to the inside of the bend. Grain direction bend line should go across the grain for the best bend having said that a typical sharp 90 bend on a piece of 1 8 aluminum sheet should be a minimum 1 8 inside radius use either 3003 or 5052 ideally the bend line should go across the grain.

Aluminum angle with 1 16 in. Set your store to see local availability compare. 3003 aluminum sheet has a smooth semi shiny finish and is popular for many applications including. Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

3003 h14 aluminum sheet astm b209 qq a 250 2 excellent weldability and formability with good corrosion resistance makes 3003 aluminum sheet a popular and economical choice. Bend along one edge. Mill finish not polished. Material bend radii and minimum bend size charts please note.

This will give you a nice bend. The bend was upward so it stuck up when placed on the trailer frame. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal.

.JPG)