Bending 4mm Aluminium Sheet

The force must exceed the material s yield strength to achieve a plastic deformation.

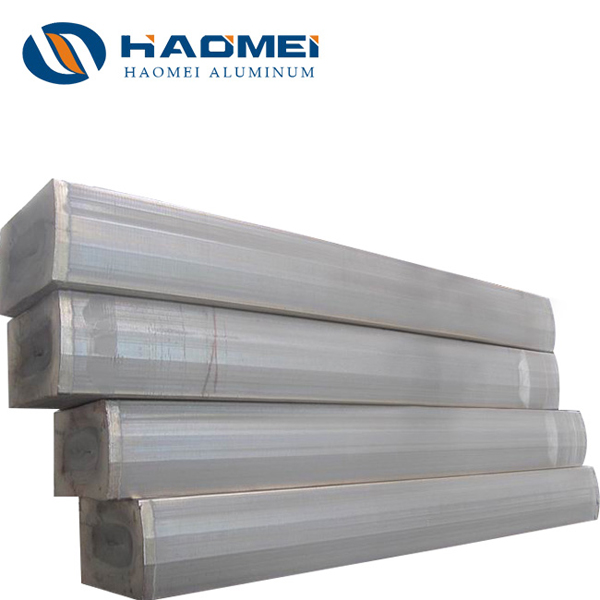

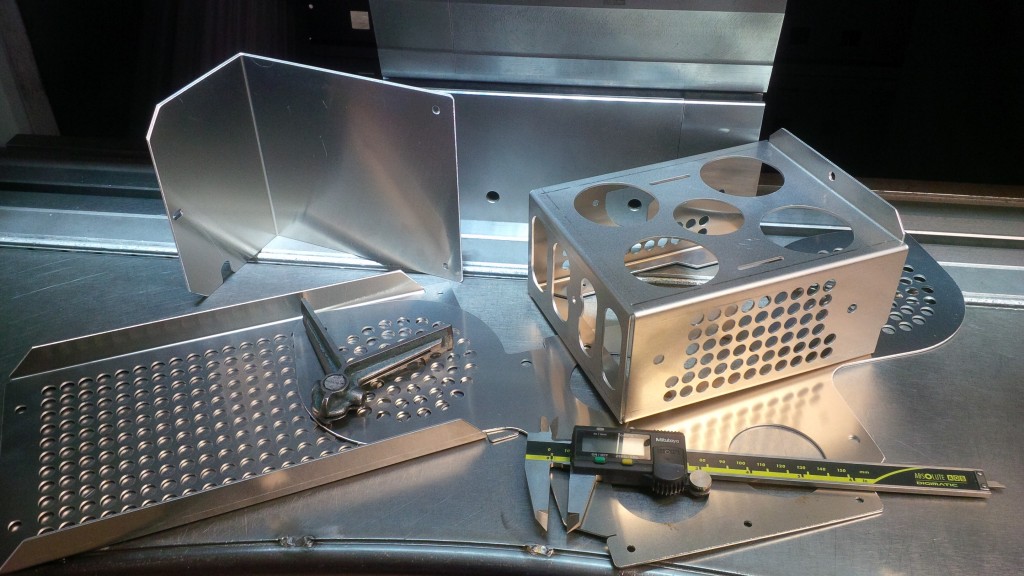

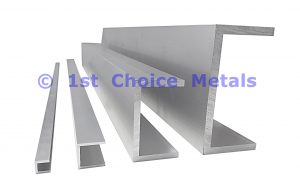

Bending 4mm aluminium sheet. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. Therefore the bend deduction equals the difference between the mold line lengths and the total flat length. How to bend sheet metal without a brake. Bending aluminium recommended press brake die set up for cold forming of sheet and plate.

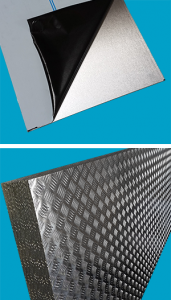

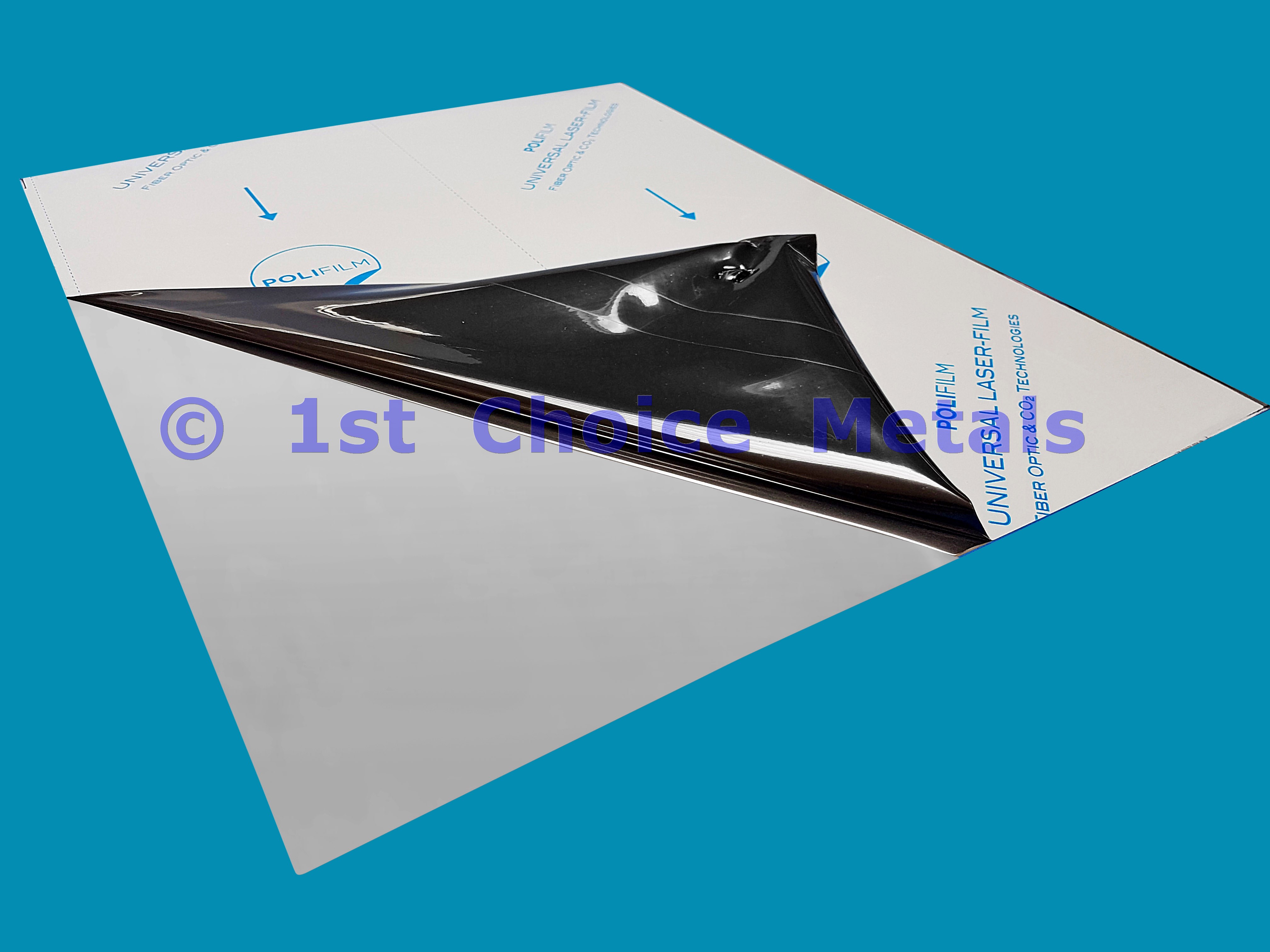

How to bend sheet metal without a brake in 4 different methods with minimal or homemade tools. With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet. This is a bending tool made at home with scrap steel made for bending 3mm checker plate aluminium. This weakens the aluminium and creates a fracture line.

0 4mm 0 8mm 1 6mm 3 0mm 4 0mm 6 0mm 10mm 12mm. Sheet metal brakes and aluminium siding brakes place clean bends on sheet aluminium. This is done through the application of force on a workpiece. The bend deduction sometimes called the bend compensation describes how much the outside of the sheet has been stretched.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape. Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend. One downfall to a brake is the cost and room required to house the equipment. Other types of bending operations may require larger radii or.

Hand bending without mechanical equipment produces clean bends with a minimal amount of tools. The bend allowance added to the flange lengths is equal to the total flat length of the part. Bending is one of the most common sheet metal fabrication operations. Place the fracture line over the edge of a table and bend the overhang slightly downwards.

.jpg)