Bending 6063 Aluminum Sheet

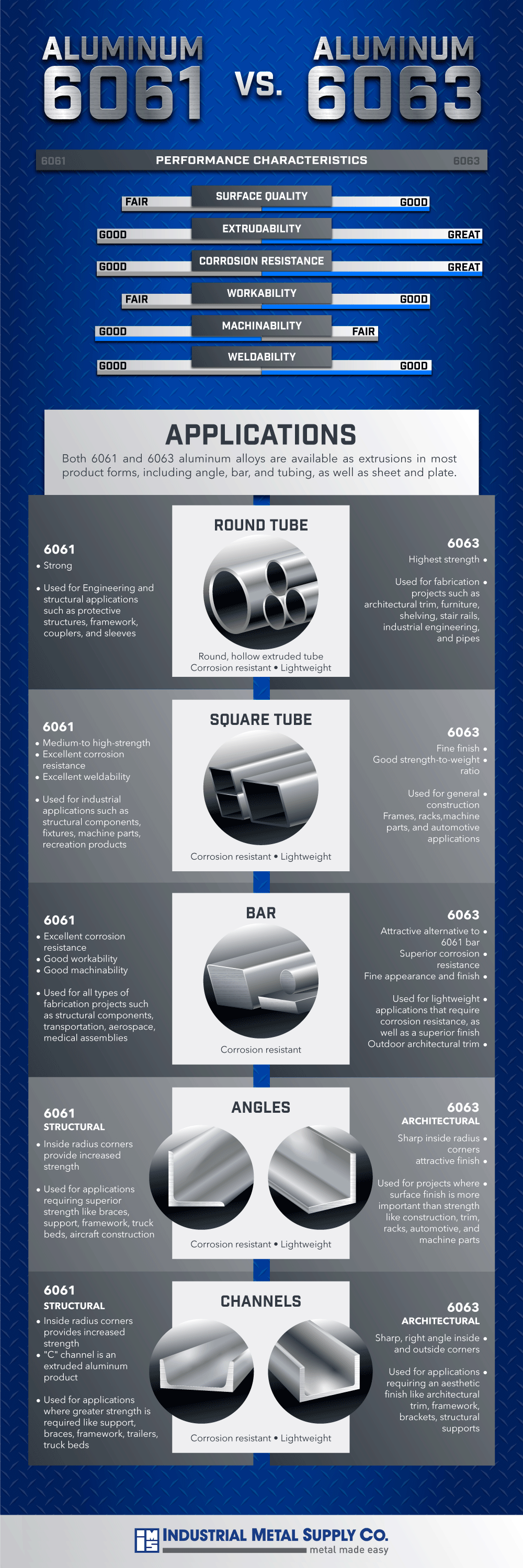

Both alloys contain magnesium for increased strength and silicon to reduce the melting temperature.

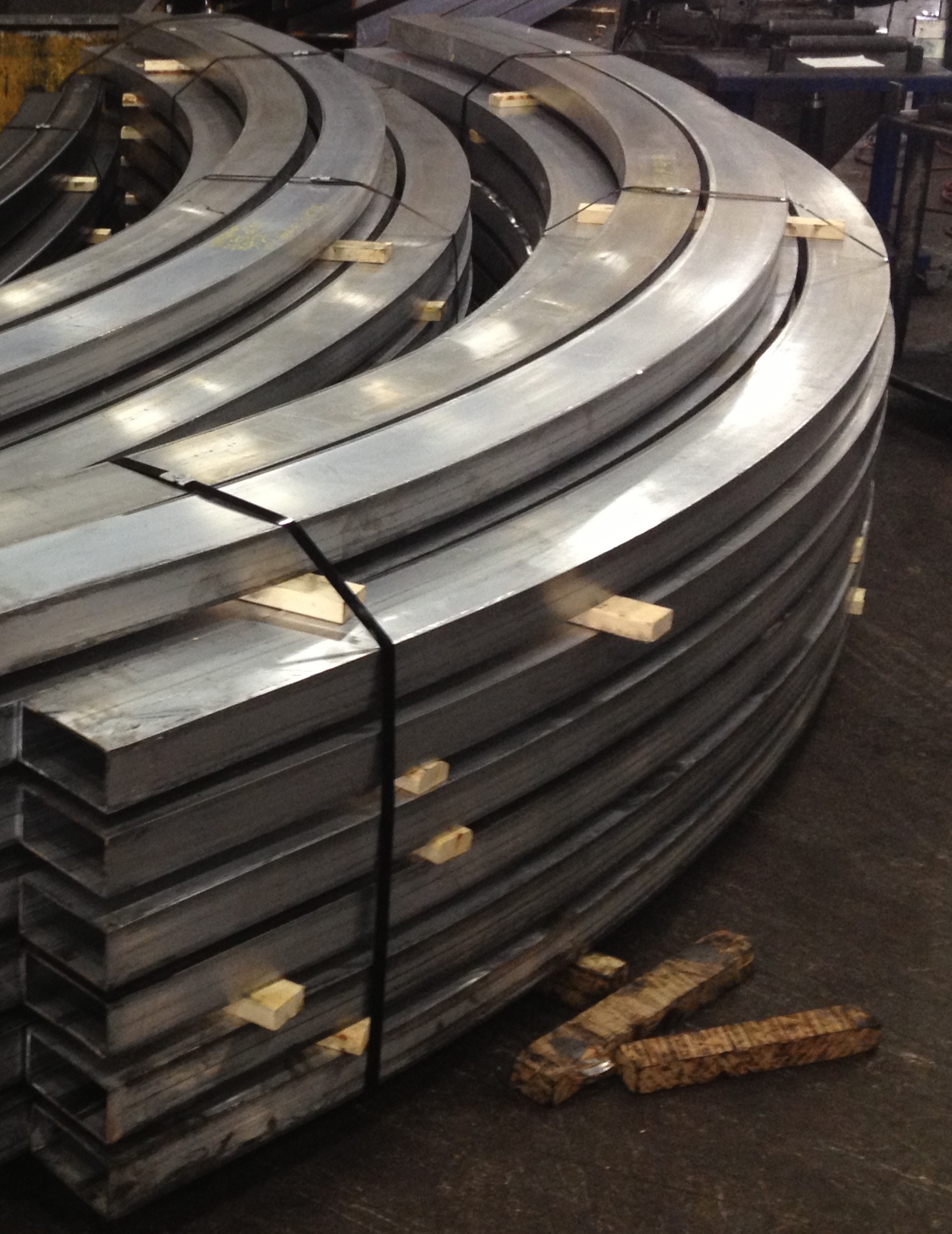

Bending 6063 aluminum sheet. 6063 is used for architectural fabrication window and door frames pipe and tubing and aluminium furniture. Aluminum 6063 aluminum 6061 and aluminum 6063 are similar in composition and mechanical properties and both are popular for extrusions. Then place the clamp bar back down on top of the aluminum crosswise. When you are forming aluminum if the radius is sharp small in relation to the material thickness you will overwork the material making it harder more brittle and much more likely to fail.

Just like all sheet metal aluminum work hardens during the forming process. Lift the clamp bar away from the rear of the brake frame and slide the sheet in perpendicularly to the direction you want to bend it. That is it gets stronger and harder by working bending it. We re having trouble bending 6061 t6 aluminum without cracking and i was wondering if you could give us a few pointers.

Typically after welding the properties near the weld are those of 6063 0 a loss of strength of up to 30. 6061 t6 aluminum is tempered and notorious for not bending easily. Place the fracture line over the edge of a table and bend the overhang slightly downwards. Radii for various thicknesses expressed in terms of thickness t.

Per the aluminum association inc. The best series for forming and thus for bending are the alloy series 3xxx 5xxx and in some cases 6xxx. In this post we ll explain it to you. Aluminium alloy 3003 excellent for bending.

Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that make your choice of proper alloy critical. Aluminum minimum bend radii for 90 degree cold forming of sheet and plate. This weakens the aluminium and creates a fracture line. Sheet aluminium can be cut without the need for a guillotine or tin snips which tend to deform the metal.

Aluminium alloy 6063 is a good choice for example while 6082 is more difficult. With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet. Which aluminum alloy bends the best is a a common question customers want the answer to. 6063 is highly weldable using tungsten inert gas welding.

In high purity forms aluminum is soft and ductile.