Bending Acrylic Sheet Max Bend

Plus you can permanently bend these plastic sheets for multiple projects like making display cases or artwork with a bending fixture a few tools and the right steps.

Bending acrylic sheet max bend. Step 1 designing. 90 degrees bend angle. Bending acrylic is something you might do if you are building a case or enclosure for an object for example. Today we re using a line bender to form some acrylic for our new cnc dust shroud.

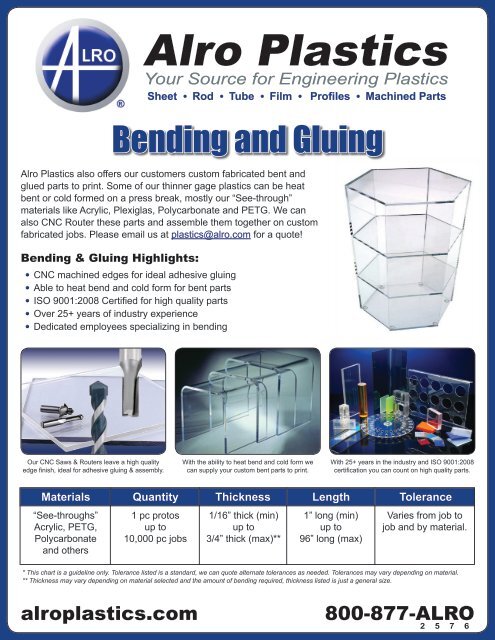

Please keep in mind the bigger and thicker the part is the more it cost to bend. If you d like to reach out to us to. Plastic bending machine is widely used in school technical courses building model decoration engineering sign making display case market shelves advertising. There are different methods for doing this and each helps you to easily bend acrylic.

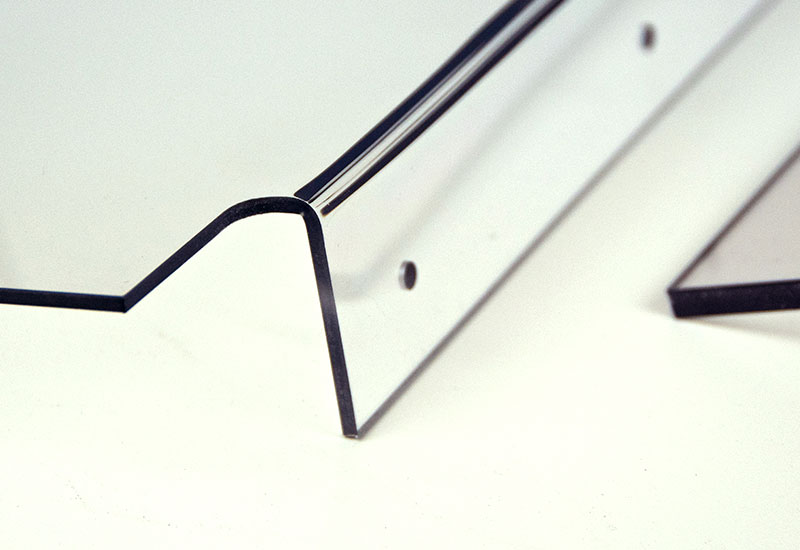

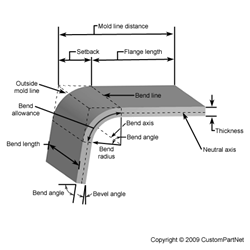

Figure 2 illustrates the sheet that is bent with the bend angle of 90 degrees. The acrylic sheet is laid over a long thin filament with the bending line just above the wire. Just be sure that you have the necessary. We will start by calculating the bend allowance.

Once you go past a 48 x 96 sheet costs can skyrocket. We re not that good at it come watch. It becomes soft and can then be properly although care must be taken. To bend acrylic sheet you will need.

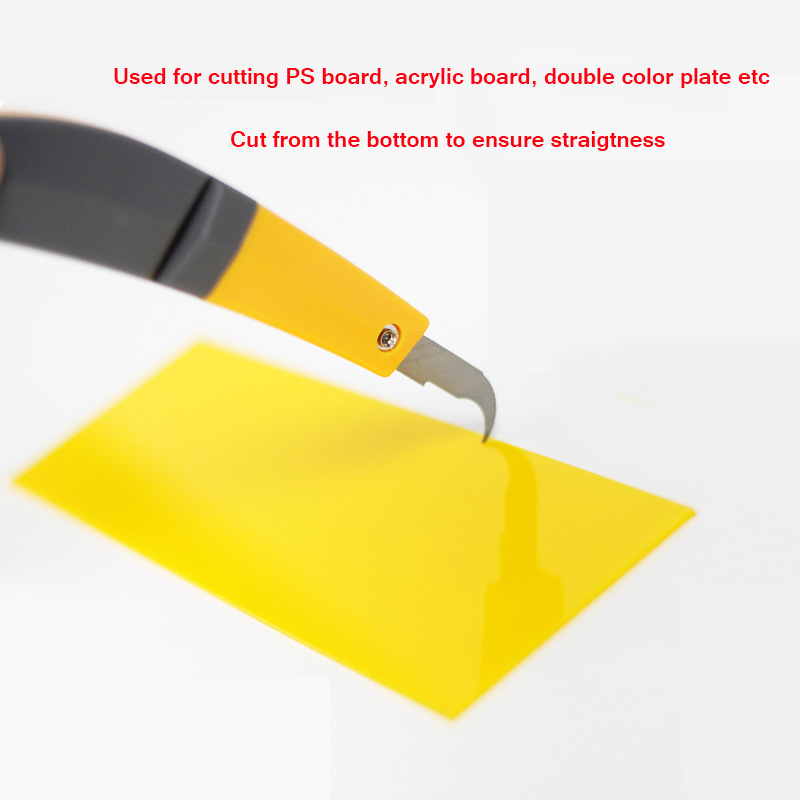

To prevent thermal damage to the sheet maximum oven air temperatures should be carefully controlled. Heat source small projects with bends that are close together will need upon heat source which can be easily aimed at small areas the two best tools for this are a small butane torch the type used in the kitchen work well or you can also use an embossing heat tool used by card makers and scrapbookers to melt and apply embossing powders. Acrylic sheets are perfect for home decor because they re affordable sturdy and come in a variety of thicknesses and colors. Bending acrylic with heat.

Manual acrylic bending machine abm700 1300 plexiglass bending machine is a useful tool for softening and bending acrylic organic glass plexiglass pvc pc abs pp sheet into shapes. Set up plastic or acrylic sheet in a simple bending jig. From there we can calculate the k factor and the bend deduction. A typical forced circulation air oven is shown.

The freight for 1 2 x 48 x 96 sheet of gray acrylic is 90 00 sometimes there is a 65 00 pallet charge. After bending the sheet we need to do some measurements as shown in figure 2. To set up your plastic or acrylic sheet to bend simple curves for your miniature and model projects you need to first remove the protective covering from the material you wish to bend. Plexiglas mc acrylic sheet 11 forming temperatures and cycles 12 time available for forming.

Use long thin 1 inch or so in width test strips to practice your technique and learn how your. If the material is at 160 degrees celsius it can be bent. First sketch out your.