Bending Ir Waves With A Sheet Of Plastic

Infrared heating can result in uneven heating if the heating elements begin to lose their heating ability over time.

Bending ir waves with a sheet of plastic. Sheet metal bending is the plastic deformation of the work over an axis creating a change in the part s geometry. To bend sheet plastic and acrylic you will need. Polycarbonate clear plastic sheet 12 x 24 x 0 0625 1 16 3 pack shatter resistant easier to cut bend mold than plexiglass. For vex robotics teams hobby diy industrial crafts.

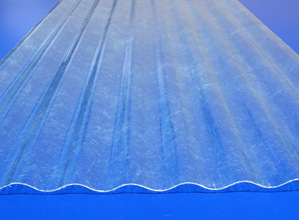

There are two tables grouped by frequency range and compound class. Also clear hard plastic sheets for structural applications. Strip heat bending utilizes infrared elements and may degrade the sheet if heating cycles are exceeded. Learn more at curbell plastics.

The two best tools for this are a small butane torch the type used in the kitchen work well or you can also use an embossing heat tool used by card makers and. Bending acrylic is something you might do if you are building a case or enclosure for an object for example. Our tanks are formed from sheet stock typically 0 25 in. There are different methods for doing this and each helps you to easily bend acrylic.

In some cases bending may produce a small change in sheet thickness. Heat source small projects with bends that are close together will need upon heat source which can be easily aimed at small areas. I am forming plastic not metal but i am applying metal bending principles to my application after a few years of iteration we have developed an accurate flat pattern method for our tank bending operations. The curves for 0 118 inch and 0 944 inch thick colorless plexiglas sheet show that near infrared transmittance depends on thickness decreasing logarithmically as thickness.

Infrared heating can degrade the sheet if the heating cycle is exceeded. Used with sheet thicknesses of less than 0 354 inches. 4 6 out of 5 stars 207. Colorless plexiglas sheet sheet transmits most of the invisible near infrared energy in the 700 to 2 800 nanometer region but it also absorbs certain bands as shown.

Similar to other metal forming processes bending changes the shape of the work piece while the volume of material will remain the same. Astm standard test methods and specifications relating to plastics their raw materials components and compounding ingredients finished products made from plastics such as sheets rods tubes pipes cellular materials and molded or fabricated articles. Thick thinned in the bent areas along the circumference and wrapped into a rectangle with radiused corners. Superior and enhanced mechanical properties for stronger stiffer plastic sheet.