Bending Sheet Metal Hardness Or Yield Strangth

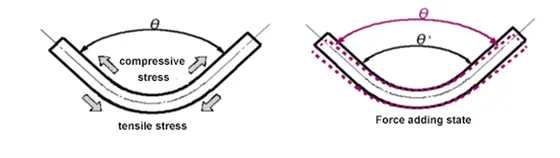

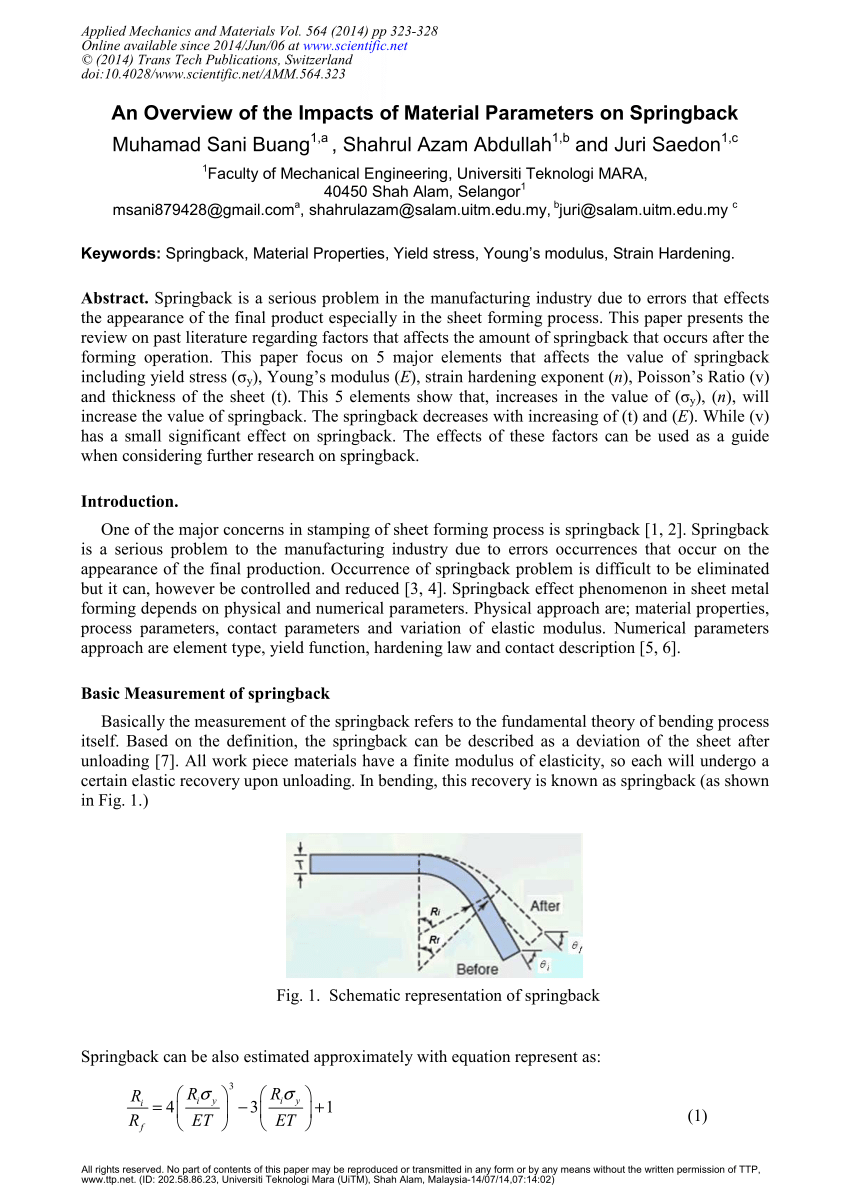

The greater the yield strength of the material the greater the spring back and the smaller the angle of the punch die should be designed for the angle of 90 degrees of the bending part.

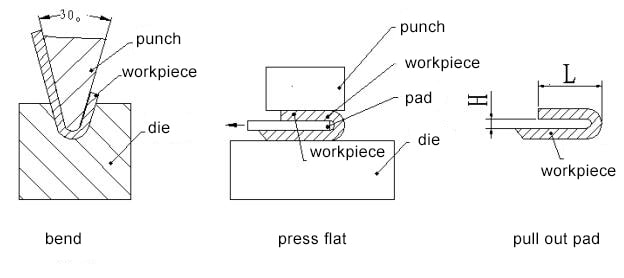

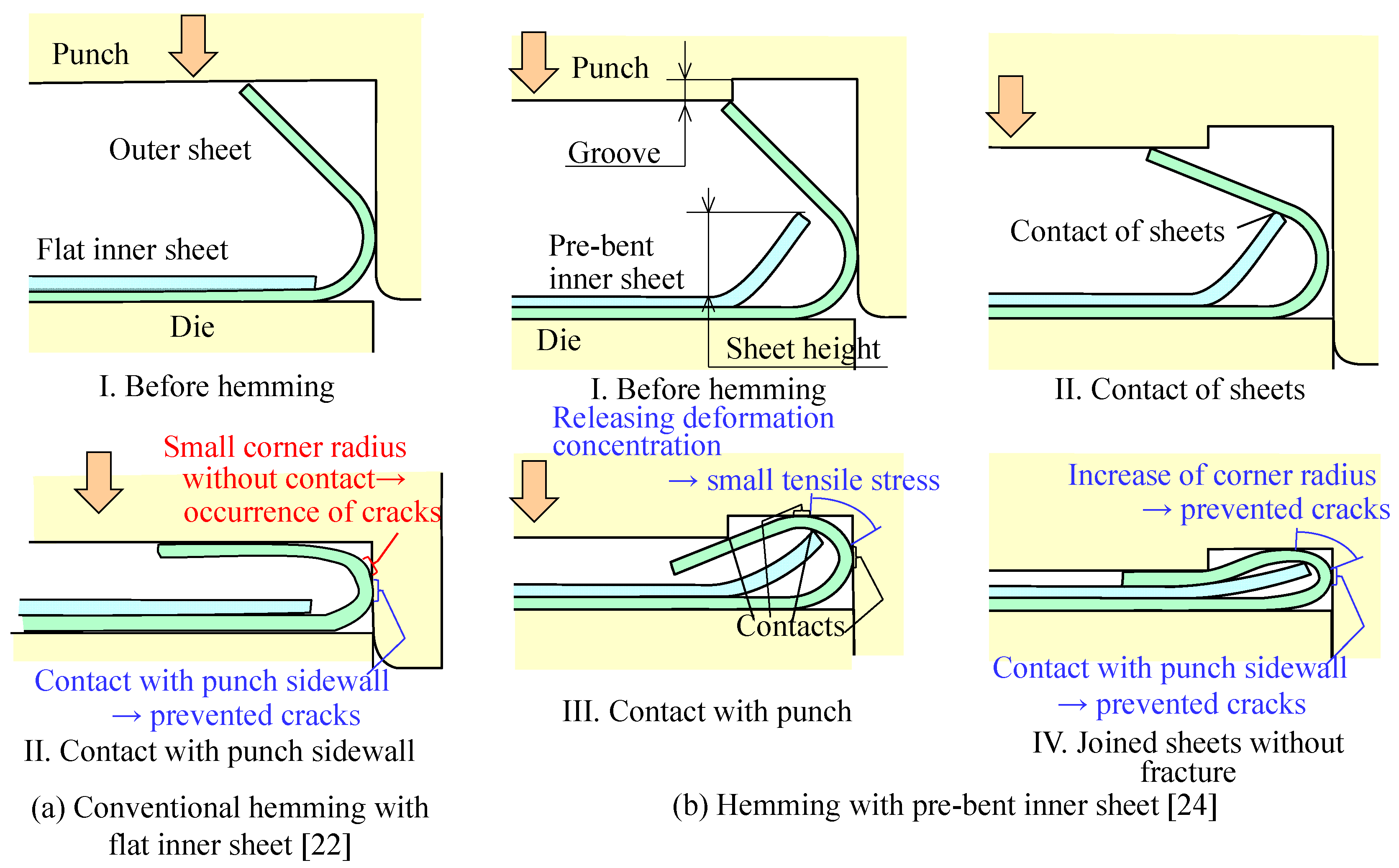

Bending sheet metal hardness or yield strangth. Offset yield strength and yield by extension under load eul were developed total elon tion offset yield stren yield strength fracture 2 byeul pgortional limit a en neerin strain e fig. It is one of the indexes of metal strength. Commonly used bends include v bend z bend offset bend and hemming bend etc. Figure 3 coining bottom bending and air forming affect stressstrain properties differently.

Each number represents the steel s yield strength. 1 3 bending of sheet metal parts. If you d like to know more about bending specific alloys or which alloy is best for your application please contact our sales department by. Bending is a stamping process that uses pressure to force the material to plastically deform.

Sheet metal bending refers to the processing of changing the angle of a sheet or panel. Sheet metal bending methods design tips k factor 11 02 2019 bending is one of the most common sheet metal fabrication operations. This is an important question when bending sheet metal as every material has its own individual load capacity with regard to yield point and tensile strength. 1 automobile bodies such as this ford 500 are dependent on the ability ofsheet metal to.

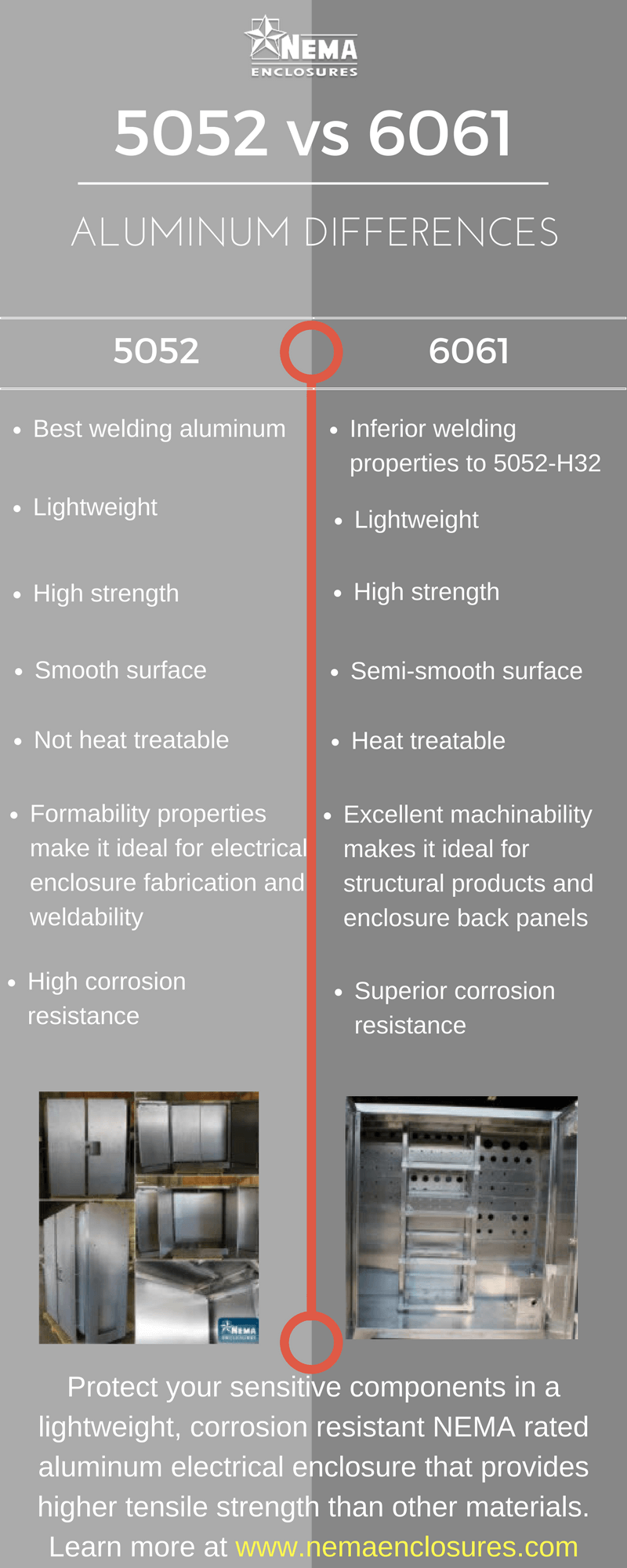

The sheet metal bending height should be at least 2 times the thickness of the sheet metal plus the bending radius that is h 2t r. Thereby forming a certain angle and curvature shape. Because ss 304 contains 18 chromium cr and 8 nickel ni it s also known as 18 8 stainless steel type 304 has good processability weldability corrosion resistance heat resistance low. Hardness a material s ability to resist a localised.

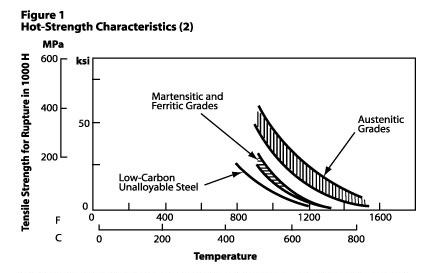

N mm2 or mpa the symbol is σb. The 700 series has a yield strength of 700 mpa whereas with strenx 900 the value is 900 mpa. Ts tensile strength of sheet metal. The curved line in the air forming zone shows how springback changes at different bend angles.

It is the maximum stress that the cross section is subjected to when the load is applied between the two points of the. In bottoming and coining bending methods that usually produce 90 degree bend angles the line curves to the right of the vertical axis showing how the metal springs forward to conform to the die angle. K bf 0 33 for edge bending. The alloy composition of the material is important as well since the addition of alloying elements can significantly affect the mechanical strength of a material.

For example the plate is bent into a v shape and u shape. 2 stress strain curve showing total elongation. K bf 1 33 for v bending. In general there are two ways to bend a sheet metal.

W part width in direction of bend axis. It is the maximum stress that the sheet metal material is subjected to before pulling out. Compared to carbon steel for the same thickness of stainless steel the bending angle is larger special attention should be paid to this point otherwise.