Beryllium Copper Contacts Sheet Mod

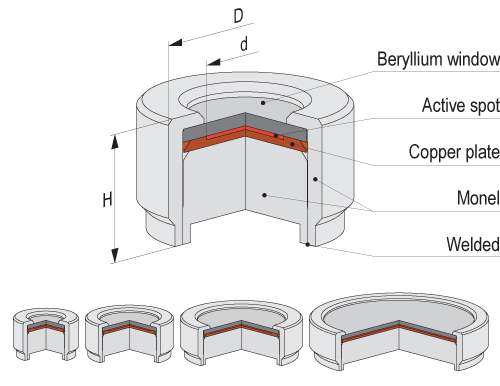

Most material that is purchased for beryllium copper contacts is uns c17200 which is certified to 97 9 copper cu 1 9 beryllium be 02 cobalt co.

Beryllium copper contacts sheet mod. Beryllium copper battery contacts are one of the more popular items manufactured here at atlantic precision spring. Beryllium copper or becu is often used in metal spring clips and flat springs because of its elastic properties formability non metallic nature and its electrical conductivity. It displays exceptional machining forming and metalworking capabilities along with a combination of high strength non magnetic and non sparking qualities. Beryllium is also found as a trace metal in slags and fly ash.

Unfortunately beryllium dust is highly toxic so manufacturing methods that create airborne particulates cannot process it. Beryllium alloys are classified into two types. 4977 is known for allowing excellent detail in your casting combined with high strength and an attractive color. 20c beryllium copper belmont product code.

Commonly stocked beryllium copper. Beryllium copper is non sparking but physically tough and nonmagnetic fulfilling the requirements of atex directive for. Beryllium copper combines high strength with non magnetic and non sparking. High beryllium content up to 30 beryllium and low beryllium content 2 3 beryllium.

Copper beryllium alloy is commonly used to make bushings bearings and springs. Beryllium copper is a non ferrous alloy used in springs spring wire load cells and other parts that must retain their shape under repeated stress and strain it has high electrical conductivity and is used in low current contacts for batteries and electrical connectors. 17410 17460 and 17510 are also obtainable. Mead metals carries alloy 172 beryllium copper in annealed quarter hard and half hard tempers from 0 003 to 0 060.

Beryllium copper alloy 20c cda 825 is our most popular offering in this category and contains 2 beryllium 0 5 cobalt and 0 25 silicon. The small ratio of beryllium to copper creates a family of high copper alloys with strength as high as alloy steel. The commercial grades of beryllium copper contain 0 4 to 2 0 percent beryllium. Beryllium copper is a material commonly specified for electrical contacts because it is electrically conductive and can be made very springy by heat treating after it has been bent to shape.

The full physical properties are density 302 lb cu in elastic modulus 10 6 psi 19 thermal expansion coefficient 70 0 f to 400 0 f 9 7 x 10 6 thermal conductivity btu ft hr 0.