Bending Cross Sectional Area In Sheet Metal

It is one of the indexes of metal strength.

Bending cross sectional area in sheet metal. Tensile yield strength x cross sectional area of bend x distance between posts on the die x a constant factor. Let α 90 θ then the irrigation canal looks like. 0 5 cos α the total area. The area of the left triangle is.

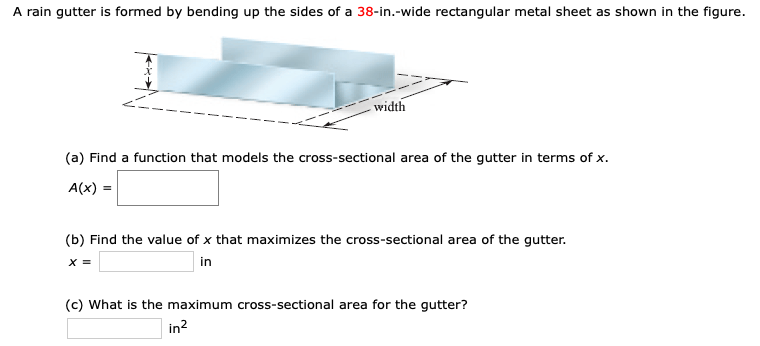

A find a function that models the cross sectional area of the gutter in terms of x. A cross sectional area of the workpiece in2 forces needed to bend sheet metal. The cross sectional ratio of strip of sheet metal and the pitch are important in plane bending conditions in this experiment. Stress is the ratio of applied load to the cross sectional area of an element in tension and isexpressed in pounds per square inch psi.

N mm2 or mpa the symbol is σb. 49 thoughts on the art and science of bending sheet metal charles veres says. Over bending stretch forming coining or bottoming the punch. It is the maximum stress that the sheet metal material is subjected to before pulling out.

Bend line the line across the metal where the punch comes in contact with the metal and the bend begins. B find the value of x that maximizes the cross sectional area of the gutter. A cos α sin α cos α. A rain gutter is formed by bending up the sides by x inches of a 30 inch wide rectangular metal sheet as shown in the figure.

For materials with poisson s ratios ν displaystyle nu close to 0 3 the shear correction factor for a rectangular cross section is approximately. The angle in the sketch is 60 degrees. It is the maximum stress that the cross section is subjected to when the load is applied between the two points of the specimen. Where is the area moment of inertia of the cross section is the cross sectional area is the shear modulus is a shear correction factor and is an applied transverse load.

When bending a piece of metal one surface of the material stretches in tension while the opposite surface compresses. Expensive sheet metal slow very high formability technology a brief review forming speed 20 1000pts hr. It follows that there is a line or region of zero stress between the. Bending the process of cold working metal to achieve a desired profile.